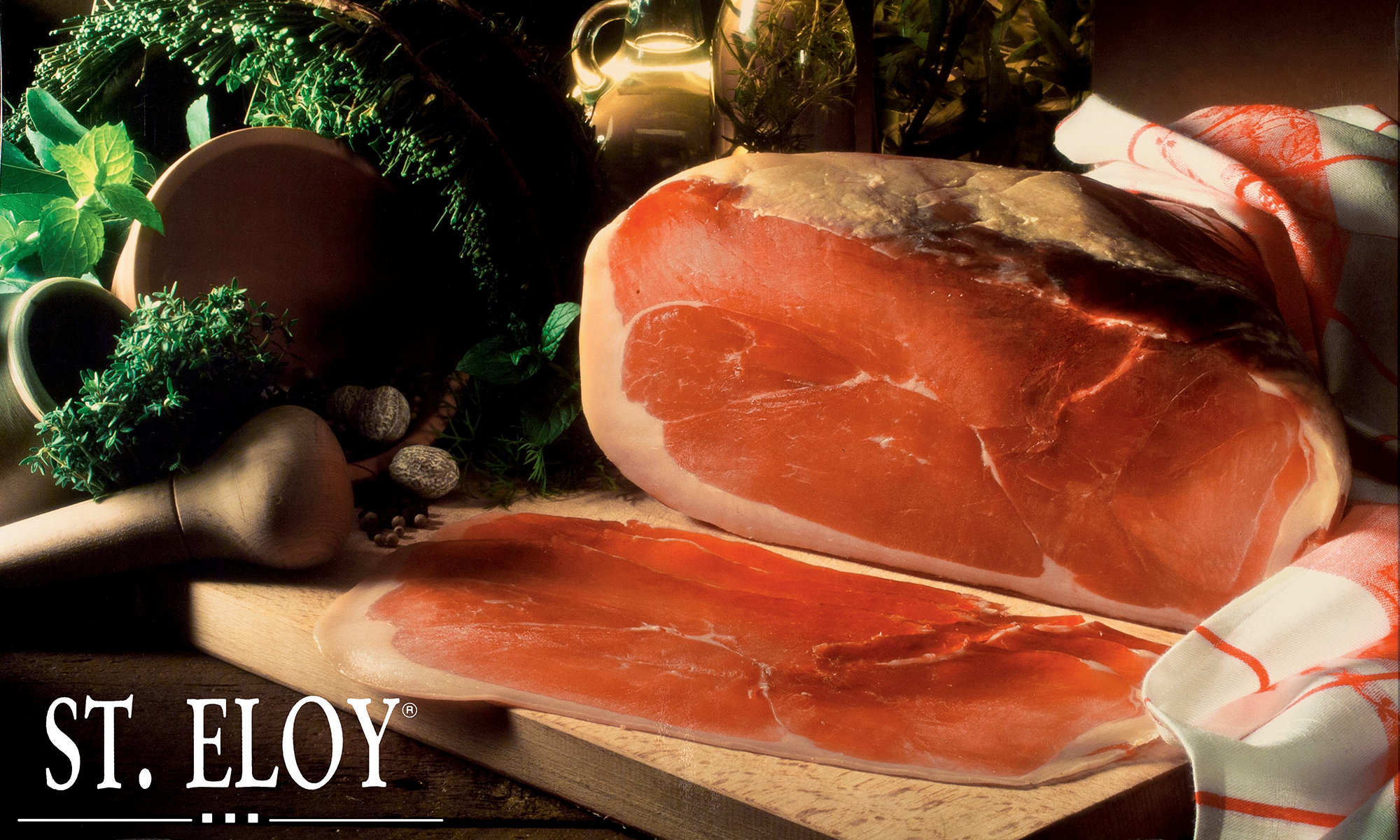

” To emphasize the traditional character of ST. ELOY® ham, it is smoked in the chimney in the traditional way ” …

The first concern starts with the choice of a healthy raw material; Belgian pigs fed with exclusively vegetable raw materials, as happened already centuries ago. Their hams contain little fat and more than 50% consist of cholesterol-lowering fatty acids.

The severely selected hams are rubbed with coarse sea salt and placed next to each other. The dry salting process takes place in 2 phases of minimum 1 week each. The gravy is preserved so that nothing of the fine taste and subtle aroma is lost.

After this dry salting method, the hams continue to mature in air-conditioned rooms for a period of 8 weeks.

To emphasize the traditional character of the ham, it is smoked in the chimney by means of beech wood, in combination with other types of wood, in the traditional way.

Finally, after the previous salt, ripening and smoking production phases, a total drying period of at least 34 weeks or longer, depending on the weight of the ham, begins.

The hams are dry-salted and dried on the bone , which benefits the taste.

It is only afterwards that they are boned, sewn and moulded. Then another final quality check is done before vacuum packaging and labeling.

The total production process lasts for 11 months or more.